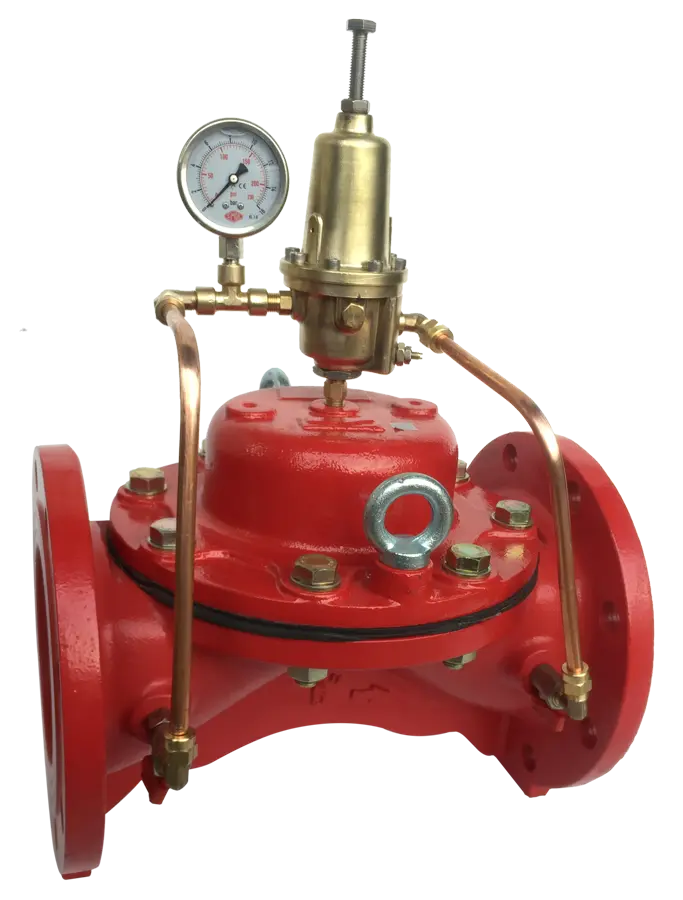

The Quick Pressure Relief Control Valve is the safety control valve designed to protect system by releasing pressure surges to atmosphere quickly caused from sudden changes in water speed because pumps put into/out of service frequently in water network elevation lines. When network pressure goes beyond set point, valve opens by itself quickly and protects system by releasing over pressure. When line pressure decreases to normal level, it is closed slowly and automatically as wholly sealed without causing surge.

Available diameters according to their connections

- FLANGED: DN50, … , DN300

- ANGLED: 2″, DN50, DN80, DN100, DN150

- THREADED: 3/4″, 1″, 1¼”, 1½”, 2″, 2½”, 3″

- VICTAULIC: 2″, 3″, 4″, 6″

Operating Pressure |

Standart | 0,7 – 16 bar (10 – 240 psi) |

| Low Pressure Range | 0,5 – 10 bar (7,5 – 160 psi) | |

| High Pressure Range | 0,7 – 25 bar (10 – 360 psi) | |

Temperature |

Min. Operating Temperature | -10 °C (14 °F) DIN 2401/2 |

| Max. Operating Temperature | 80 °C (176 °F) DIN 2401/2 | |

Port |

Flanged | DIN 2501, ISO 7005 – 2 |

| Threaded | ISO (BSP) , ANSI (NPT) | |

Coating |

Standard | Epoxy |

| Optional | Polyester | |

Hydraulic Links |

Standard | Reinforced Nylon (Air Brake)) Hydraulic pipe SAE J 844 |

| Optional | Copper DIN 1057 | |

Actuator Type |

Single-Control Housing | Aperture Actuator, Aperture Off | |

Automatic control valves are used to perform the required operations as hydraulic with line pressure without the need for energy sources in the network line.

Valve Closing Mode

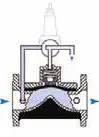

When the water pressure reaches the diaphragm, the water creates hydraulic force. This hydraulic force diaphragm, combined with the force applied by the spring creates a complete seal and allows it to close.

Valve Opening Mode

When the pilot on the main control valve in the closed position is placed in the evacuation position, pressurized water on the diaphragm of the main control valve is discharged. When the line pressure reaches the position to overcome the spring force, it applies hydraulic force from the bottom to the diaphragm of the control valve and allows the valve to reach the full open position

Modulation Mode

They are pilots connected to the control valve which enables the main valve to operate in this position. According to the amount of flow and pressure required to be adjusted, it controls the water pressure on the diaphragm continuously and allows it to operate in modulated position.

- Easy operation and maintenance with simple structure

- Low cost

- Working at wide pressure value range

- Perfect modulation even at low flow rates

- Continuous on / off with flexible aperture

- Full seal with reinforced diaphragm and inner spring

- Long life with epoxy-polyester coating

- Wide range of control area with the use of different pilot valves

- Ability to work in horizontal and vertical positions in application areas

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Valve Diameter |

2 | 50 | 2½ | 65 | 3 | 80 | 4 | 100 | 5 | 125 | 6 | 150 | 8 | 200 | 10 | 250 | 12 | 300 |

CV m³/h @ 1 bar |

88 | 88 | 174 | 187 | 187 | 419 | 1139 | 1698 | 2276 | |||||||||

Kv gpm @ 1 bar |

102 | 102 | 201 | 216 | 216 | 484 | 1316 | 1961 | 2629 | |||||||||

KV: Valve flow Coefficient (Flow Rate At 1 Bar Pressure Loss M³/h @ 1 BAR)

CV: Valve flow Coefficient (Flow in pressure lossof 1 Psi GPM @ 1 Psi)

Q: Flow (M³/h, GPM)

ΔP: Pressure Loss (BAR, PSİ)

G: Specific Gravity of Water (For water = 1.0)

Installation

- Quick relief control valve is installed in the Te configuration of the network system.

- Since the function of the valve is discharged, the valve diameter can be selected as equal to or smaller than the main pipe diameter.

- Valve closing time is proportional to pipe length. As the pipe length of the system increases, valve closing time should be increased.

Adjusting

- Turn on the pump or turn on the mains main valve and give water to the system.

- Open spherical valves indicated by “2” and “2/1”.

- Wait a few seconds for the water to reach the control Chamber of the valve. When water reaches the control chamber, the manometer needle will show a

certain pressure value. - Adjust the desired input pressure value with the adjustment Bolt indicated by “5” on the pilot indicated by “1” by looking at the manometer indicated by “4”

- When you turn adjustment Bolt Clockwise, the input pressure value will increase, turning in the opposite direction if the input pressure value will decrease.

After adjusting the desired inlet pressure value, tighten the nut under the adjustment Bolt. The manometer on the valve shows the input pressure value.

After adjusting the desired inlet pressure value, tighten the nut under the adjustment Bolt. The manometer on the valve shows the input pressure value.

Treatment

- Check and clean the finger filter indicated by “3” due to the particles that may accumulate on it. Do not do more than one filter cleaning in a few months unless the water is very dirty.

- Drain water from the unused valve and pilot during winter.

FLANGED |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | |

| inch | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | ||

|

||||||||||

Port |

Flanged | |||||||||

Material |

GG25 – GGG40 | |||||||||

Body |

Globe | |||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | |||||||||

VICTAULIC |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 50 | 65 | 80 | 100 | 150 | |||

| inch | 2 | 2½ | 3 | 4 | 6 | ||||

|

|||||||||

Port |

Victaulic | ||||||||

Material |

GG25 – GGG40 | ||||||||

Body |

Globe | ||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | ||||||||

THREADED |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 25 | 40 | 50 | 65 | 80×50 | 80 | ||

| inch | 1 | 1½ | 2 | 2½ | 3x2x3 | ||||

|

|||||||||

Port |

Threaded | ||||||||

Material |

GG25 – GGG40 | ||||||||

Body |

Globe | ||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | ||||||||

ANGELED |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 50 | 80 | 100 | 150 | ||||

| inch | 2 | 3 | 4 | 6 | |||||

|

|||||||||

Port |

Flange – Threaded | ||||||||

Material |

GG25 – GGG40 | ||||||||

Body |

Globe | ||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | ||||||||