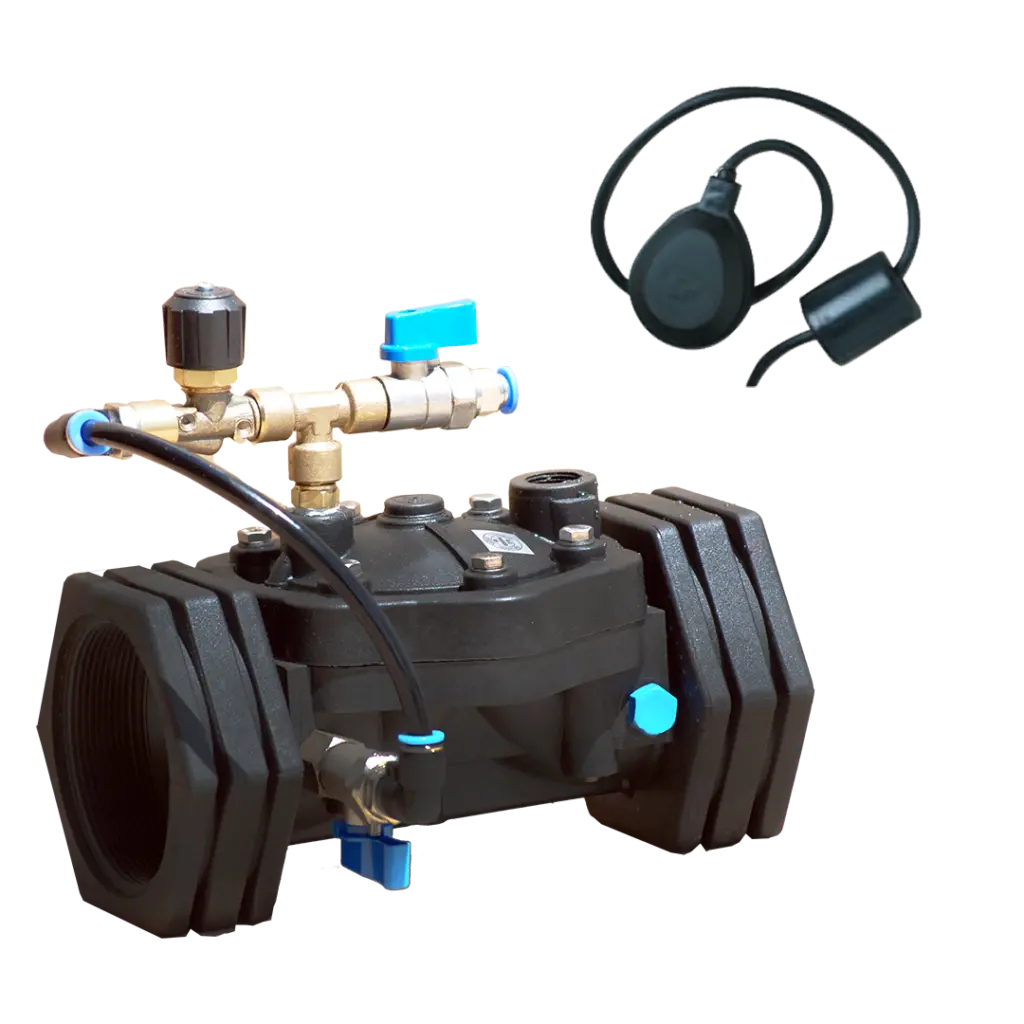

Electric Float Level Control Valve is a valve that constantly controls water level by electric float placed in the tank. When the water level at the bottom falls below the desired value, the electric floater sends a signal to the solenoid coil on the main valve. This allows the valve to open itself fully and keep the reservoir constantly full. When the water level reaches the maximum level, the electric switch sends a signal again to the solenoid coil and the valve closes itself. The valve can be operated on the system horizontally or vertically.

Existing Diameters According To Their Connections

- Flanged: DN80, DN100

- Angled : 2″, 3″

- Threaded: 3/4″, 1″, 1½”, 2″, 2½”, 3R, 3″ , 4″

It is a fully automatic hydraulic control valve designed to perform the hydraulically desired modulation processes with the line pressure without the need for different energy sources such as electricity, pneumatic or mechanical in the main valve mains line

Valve Closing Mode

Pilot valves connected to the main valve create a hydraulic force on the valve diaphragm when the water pressure at the valve inlet reaches the actuator actuator (control reservoir) of the valve. This hydraulic force that is created combines the diaphragm of the valve with the extra force exerted by the internal spring to ensure a tight seal.

Valve Opening Mode

When the path of the pilot valve on the main valve in the closed position is set to the discharge position, the pressurized water in the control chamber on the diaphragm of the main valve is discharged. When the line pressure reaches the spring force, the valve diaphragm applies a hydraulic force to the diaphragm to bring the valve into the full open position.

Modulation Mode

The pilot valves that connect the actuator to the main valve allow the main valve to operate in the modulated position. The valve in the actuator of the main valve (control reservoir), according to the flow quantity or pressure conditions to be adjusted, ensures that the fluid continuously operates in the modulated position by controlling the pressure.

- Easy operation and maintenance with simple structure

- Low cost

- Working at wide pressure value range

- Perfect modulation even at low flow rates

- Continuous on / off with flexible aperture

- Full seal with reinforced diaphragm and inner spring

- Long life with epoxy-polyester coating

- Wide range of control area with the use of different pilot valves

- Ability to work in horizontal and vertical positions in application areas