Operating Pressure |

Standart | 0,7 – 16 bar (10 – 240 psi) |

| Low Pressure Range | 0,5 – 10 bar (7,5 – 160 psi) | |

| High Pressure Range | 0,7 – 25 bar (10 – 360 psi) | |

Temperature |

Min. Operating Temperature | -10 °C (14 °F) DIN 2401/2 |

| Max. Operating Temperature | 80 °C (176 °F) DIN 2401/2 | |

Port |

Flanged | DIN 2501, ISO 7005 – 2 |

| Threaded | ISO (BSP) , ANSI (NPT) | |

Coating |

Standard | Epoxy |

| Optional | Polyester | |

Hydraulic Links |

Standard | Reinforced Nylon (Air Brake)) Hydraulic pipe SAE J 844 |

| Optional | Copper DIN 1057 | |

Actuator Type |

Single-Control Housing | Aperture Actuator, Aperture Off | |

Automatic control valves are used to perform the required operations as hydraulic with line pressure without the need for energy sources in the network line.

Valve Closing Mode

When the water pressure reaches the diaphragm, the water creates hydraulic force. This hydraulic force diaphragm, combined with the force applied by the spring creates a complete seal and allows it to close.

Valve Opening Mode

When the pilot on the main control valve in the closed position is placed in the evacuation position, pressurized water on the diaphragm of the main control valve is discharged. When the line pressure reaches the position to overcome the spring force, it applies hydraulic force from the bottom to the diaphragm of the control valve and allows the valve to reach the full open position

Modulation Mode

They are pilots connected to the control valve which enables the main valve to operate in this position. According to the amount of flow and pressure required to be adjusted, it controls the water pressure on the diaphragm continuously and allows it to operate in modulated position.

- Easy operation and maintenance with simple structure

- Low cost

- Working at wide pressure value range

- Perfect modulation even at low flow rates

- Continuous on / off with flexible aperture

- Full seal with reinforced diaphragm and inner spring

- Long life with epoxy-polyester coating

- Wide range of control area with the use of different pilot valves

- Ability to work in horizontal and vertical positions in application areas

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Valve Diameter |

2 | 50 | 2½ | 65 | 3 | 80 | 4 | 100 | 5 | 125 | 6 | 150 | 8 | 200 | 10 | 250 | 12 | 300 |

CV m³/h @ 1 bar |

88 | 88 | 174 | 187 | 187 | 419 | 1139 | 1698 | 2276 | |||||||||

Kv gpm @ 1 bar |

102 | 102 | 201 | 216 | 216 | 484 | 1316 | 1961 | 2629 | |||||||||

KV: Valve flow Coefficient (Flow Rate At 1 Bar Pressure Loss M³/h @ 1 BAR)

CV: Valve flow Coefficient (Flow in pressure lossof 1 Psi GPM @ 1 Psi)

Q: Flow (M³/h, GPM)

ΔP: Pressure Loss (BAR, PSİ)

G: Specific Gravity of Water (For water = 1.0)

Installation

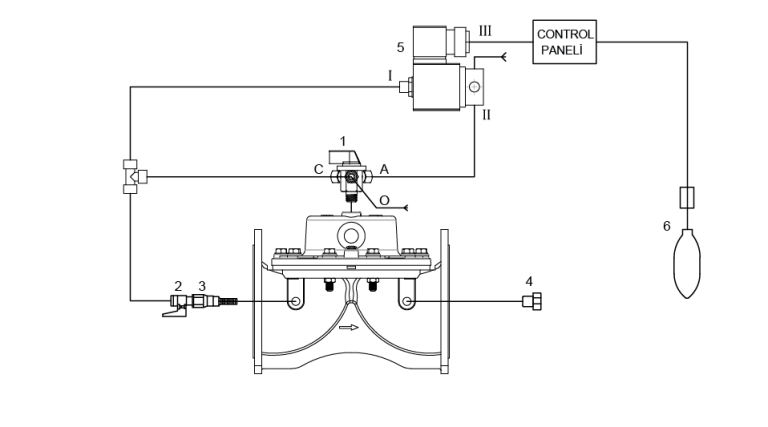

- After connecting to Valve inlet, finger filter number 3 and mini ball valve number 2, it is connected to the closed “C” outlet of 3-way valve with the help of copper or plastic pipe and to the “I” outlet of solenoid valve.

- “II” output of solenoid valve No. 5 is connected to the control panel with “III” output to Auto “A” output of 3-way valve.

- Valve outlet” 4 ” is connected to the blind.

- In the direction of the arrow indicated on the valve Mount.

- When mounting the valve, place sealing seals between the valve flange and the pipe flange and tighten bolts in caplock.

- Isolation valves (butterfly or sliding valve etc.) in the line Assembly of the valve.B) it is recommended to use air discharge valve, quick pressure discharge control valve (QR) and dirt retaining valves.

Adjusting

- The electric flat switch shown with “6” is fixed according to the water level in the tank or reservoir mount and connect the cables to the control panel.

- Connect the cables of solenoid pilot valve indicated by “5” in accordance with the control panel.

- Auto position of 3-way selector valve indicated by “1” on main valve.

- Open the global valve indicated by “2”.

Three-Way Mini Ball Valve

Three-Way Mini Ball Valve- Mini Ball Valve

- Finger Filter

- Blind plug

- Solenoid Valve

- Electric Float Switch

FLANGED |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | |

| inch | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | ||

|

||||||||||

Port |

Flanged | |||||||||

Material |

GG25 – GGG40 | |||||||||

Body |

Globe | |||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | |||||||||

VICTAULIC |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 50 | 65 | 80 | 100 | 150 | |||

| inch | 2 | 2½ | 3 | 4 | 6 | ||||

|

|||||||||

Port |

Victaulic | ||||||||

Material |

GG25 – GGG40 | ||||||||

Body |

Globe | ||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | ||||||||

THREADED |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 25 | 40 | 50 | 65 | 80×50 | 80 | ||

| inch | 1 | 1½ | 2 | 2½ | 3x2x3 | ||||

|

|||||||||

Port |

Threaded | ||||||||

Material |

GG25 – GGG40 | ||||||||

Body |

Globe | ||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | ||||||||

ANGELED |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 50 | 80 | 100 | 150 | ||||

| inch | 2 | 3 | 4 | 6 | |||||

|

|||||||||

Port |

Flange – Threaded | ||||||||

Material |

GG25 – GGG40 | ||||||||

Body |

Globe | ||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | ||||||||