The Surge Anticipating Control Valve i is the safety control valve designed to protect system in relatively longer water supply network elevating line by damping energy waves formed by energy interruptions in pumping systems and by releasing waterhammers which are caused from sudden changes in water flow rate to atmosphere automatically and quickly. Valve is opened quickly by sensing diminished pressure wave previously by means of pressure signal tube it owned. When line pressure reached normal level, it is closed slowly and automatically as wholly sealed

Existing Diameters According To Their Connections

- Flanged: DN50, … , DN300

- Angled: 2″, DN50, DN80, DN100, DN150

- Threaded : 3/4″, 1″, 1¼”, 1½”, 2″, 2½”, 3″

- Victaulic : 2″, 3″, 4″, 6″

Operating Pressure |

Standart | 0,7 – 16 bar (10 – 240 psi) |

| Low Pressure Range | 0,5 – 10 bar (7,5 – 160 psi) | |

| High Pressure Range | 0,7 – 25 bar (10 – 360 psi) | |

Temperature |

Min. Operating Temperature | -10 °C (14 °F) DIN 2401/2 |

| Max. Operating Temperature | 80 °C (176 °F) DIN 2401/2 | |

Port |

Flanged | DIN 2501, ISO 7005 – 2 |

| Threaded | ISO (BSP) , ANSI (NPT) | |

Coating |

Standard | Epoxy |

| Optional | Polyester | |

Hydraulic Links |

Standard | Reinforced Nylon (Air Brake)) Hydraulic pipe SAE J 844 |

| Optional | Copper DIN 1057 | |

Actuator Type |

Single-Control Housing | Aperture Actuator, Aperture Off | |

Automatic control valves are used to perform the required operations as hydraulic with line pressure without the need for energy sources in the network line.

Valve Closing Mode

When the water pressure reaches the diaphragm, the water creates hydraulic force. This hydraulic force diaphragm, combined with the force applied by the spring creates a complete seal and allows it to close.

Valve Opening Mode

When the pilot on the main control valve in the closed position is placed in the evacuation position, pressurized water on the diaphragm of the main control valve is discharged. When the line pressure reaches the position to overcome the spring force, it applies hydraulic force from the bottom to the diaphragm of the control valve and allows the valve to reach the full open position

Modulation Mode

They are pilots connected to the control valve which enables the main valve to operate in this position. According to the amount of flow and pressure required to be adjusted, it controls the water pressure on the diaphragm continuously and allows it to operate in modulated position.

- Easy operation and maintenance with simple structure

- Low cost

- Working at wide pressure value range

- Perfect modulation even at low flow rates

- Continuous on / off with flexible aperture

- Full seal with reinforced diaphragm and inner spring

- Long life with epoxy-polyester coating

- Wide range of control area with the use of different pilot valves

- Ability to work in horizontal and vertical positions in application areas

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

inch |

mm |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Valve Diameter |

2 | 50 | 2½ | 65 | 3 | 80 | 4 | 100 | 5 | 125 | 6 | 150 | 8 | 200 | 10 | 250 | 12 | 300 |

CV m³/h @ 1 bar |

88 | 88 | 174 | 187 | 187 | 419 | 1139 | 1698 | 2276 | |||||||||

Kv gpm @ 1 bar |

102 | 102 | 201 | 216 | 216 | 484 | 1316 | 1961 | 2629 | |||||||||

KV: Valve flow Coefficient (Flow Rate At 1 Bar Pressure Loss M³/h @ 1 BAR)

CV: Valve flow Coefficient (Flow in pressure lossof 1 Psi GPM @ 1 Psi)

Q: Flow (M³/h, GPM)

ΔP: Pressure Loss (BAR, PSİ)

G: Specific Gravity of Water (For water = 1.0)

Installation

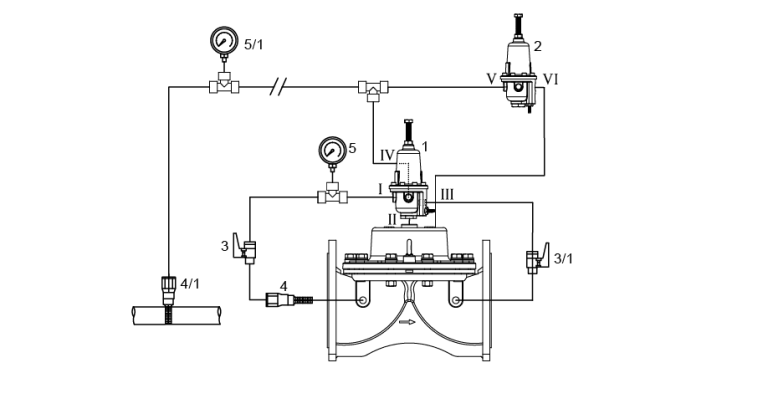

- After the veya 4 ”finger filter and the bakır 3 boru mini ball valve are connected to the valve inlet, connection to the“ I “outlet of the pressure stabilizer pilot is provided by means of copper or plastic pipe.

- Valve cap of the pressure stabilizer pilot vana II eleman is connected to the valve cap.

- Connect the mini ball valve 3/1 to the valve outlet. From here, the connection to the ”III“ output of the pressure stabilizer pilot is provided.

- The. IV “output of the pressure stabilizer pilot is connected to the düşür V un output of the pressure reducing pilot.

- The ıyla VI eleman output of the pressure reducing pilot is connected to the valve cover by the necessary fasteners.

- Install the valve on the line “TE”.

- Mount the pressure signal pipe of the valve on the main line.

- Mount the valve in the direction of the arrow indicated on it.

- When connecting the valve to the line, put a gasket between the valve flange and the pipe flange to ensure sealing. tighten the bolts in the cap.

- It is recommended to use isolating valves (butterfly or gate valve etc.), air relief valve, quick pressure relief control valve (QR) and strainer valves in the line of the valve.

- Risk of cavitation during pressure drop is dangerous for the valve body. Adjust the output pressure value that you want to adjust by looking at the cavitation chart or contact our company.

Adjusting

High Pressure Pilot Setings

- Loosen the adjustment bolt of the low pressure pilot valve indicated by “1” (1/1) and gently tighten the adjustment bolt of the high pressure pilot valve indicated by “2” (2/1).

- Turn off the ball valves shown with “3/2” and “3/3” and start the pump.

- When the system pressure reaches the operating pressure, open the valve indicated with “3/3” and loosen the “2/1” adjustment Bolt until the water drops from the “3/3” global valve. After starting to drip water, turn the adjustment screw in the opposite direction until 1 round and tighten the Contra nut under it. The setting point of the high pressure pilot valve is usually set to 1 bar higher than the system pressure.

- Turn on the “3/2” ball valve and adjust the low pressure pilot valve indicated by “1”.

Low Pressure Pilot Setings

Close the spherical valve indicated by “3/4”.

Close the spherical valve indicated by “3/4”.- Slowly open the needle valve indicated by “6”.

- Check the pressure from the “5” manometer. The pressure will drop.

- When the pressure drops, the “3/2” will start to drip water from the global valve.

- After the water starts dripping, close the needle valve indicated by “6” and open the “3/4” ball valve.

- Set the low pressure pilot valve “1” opening pressure to the desired value with the adjustment Bolt “1/1” if it is not in the desired value. If the low pressure wave (valve opening pressure) is too high, loosen the “1/1” adjustment Bolt 1/2 laps. If the low pressure wave is too low, tighten the “1/1” adjustment screw 1/2 lap. Adjust each low pressure pilot valve setting according to the instructions above.

- Pressure Stabilizer Pilot

- Pressure Lowering Pilot

- Mini Ball Valve

- Finger Filter

- Manometer

FLANGED |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | |

| inch | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | ||

|

||||||||||

Port |

Flanged | |||||||||

Material |

GG25 – GGG40 | |||||||||

Body |

Globe | |||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | |||||||||

VICTAULIC |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 50 | 65 | 80 | 100 | 150 | |||

| inch | 2 | 2½ | 3 | 4 | 6 | ||||

|

|||||||||

Port |

Victaulic | ||||||||

Material |

GG25 – GGG40 | ||||||||

Body |

Globe | ||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | ||||||||

THREADED |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 25 | 40 | 50 | 65 | 80×50 | 80 | ||

| inch | 1 | 1½ | 2 | 2½ | 3x2x3 | ||||

|

|||||||||

Port |

Threaded | ||||||||

Material |

GG25 – GGG40 | ||||||||

Body |

Globe | ||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | ||||||||

ANGELED |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

Available Diameters |

mm | 50 | 80 | 100 | 150 | ||||

| inch | 2 | 3 | 4 | 6 | |||||

|

|||||||||

Port |

Flange – Threaded | ||||||||

Material |

GG25 – GGG40 | ||||||||

Body |

Globe | ||||||||

Transmission Pressure |

PN10 – PN16 – PN25 | ||||||||